Introduction:

Cooling towers play a crucial role in various industrial processes by efficiently managing heat dissipation and ensuring the optimal functioning of machinery. These towering structures are not only integral to the smooth operation of power plants, کولینگ تاور, and manufacturing facilities but also contribute significantly to environmental sustainability. In this article, we will explore the functions, types, and environmental impact of cooling towers.

- Understanding the Basics:

Cooling towers are heat rejection devices that transfer excess heat from industrial processes to the atmosphere. They operate on the principle of evaporative cooling, where a small amount of water is evaporated to remove heat and cool the process fluid. This ingenious mechanism prevents equipment overheating, enhancing overall efficiency.

- Types of Cooling Towers:

There are several types of cooling towers, each designed to suit specific industrial needs. The main classifications include:

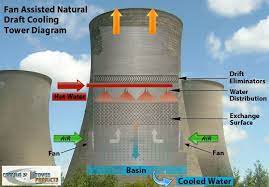

a. Natural Draft Cooling Towers:

– Utilize the buoyancy of air to facilitate natural airflow.

– Often found in large power plants and industrial complexes.

b. Mechanical Draft Cooling Towers:

– Employ mechanical means, such as fans or blowers, to enhance airflow.

– Divided into induced draft and forced draft systems.

c. Crossflow and Counterflow Cooling Towers:

– Differ in the direction of air and water flow.

– Crossflow towers have perpendicular air and water streams, while counterflow towers have parallel streams.

d. Open and Closed Circuit Cooling Towers:

– Open circuit towers allow direct contact between air and process fluid.

– Closed circuit towers use a heat exchanger to separate the process fluid from the air, preventing contamination.

- Efficiency and Energy Conservation:

Cooling towers contribute to energy conservation by efficiently dissipating heat. The evaporative cooling process requires less energy compared to other methods, making it an environmentally friendly option. Regular maintenance and optimization further enhance efficiency, ensuring the longevity of the cooling tower system.

- Environmental Impact:

While cooling towers are essential for industrial processes, they can have environmental implications. The release of warm water into natural water bodies can impact aquatic ecosystems. To mitigate these effects, industries are adopting advanced technologies like cooling pond systems and hybrid cooling towers, which minimize water usage and reduce environmental impact.

- Technological Advancements:

Recent advancements in cooling tower technology focus on improving energy efficiency, water conservation, and overall performance. Intelligent control systems, variable speed fans, and innovative materials contribute to more sustainable and eco-friendly cooling solutions.

- Conclusion:

Cooling towers stand as silent giants, ensuring the reliability and efficiency of industrial processes while playing a vital role in environmental stewardship. As industries continue to evolve, the integration of cutting-edge technologies and sustainable practices in cooling tower design will undoubtedly shape a future where efficiency and environmental responsibility go hand in hand.

More Stories

The Cultural Phenomenon of Fake Taxi: An Exploration of Its Impact on Adult Entertainment and Popular Culture

라오스는 동남아시아의 매력적인 나라로, 풍부한 자연경관과

The Evolving Landscape of Real Estate: Trends and Insights for 2024